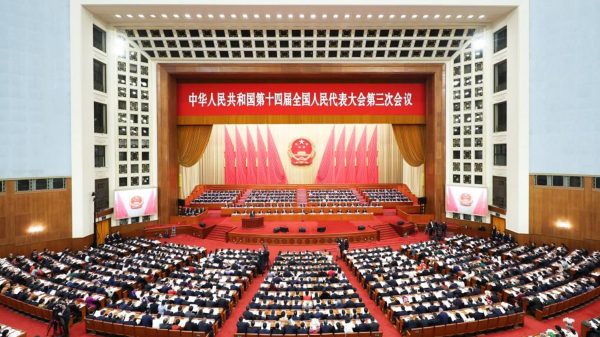

The Intergovernmental Negotiating Committee, which includes most UN member states, plans to finalize the development of an international legally binding document at a meeting in Seoul in November 2024 to combat plastic pollution.

The document will focus on the collection of plastic and its incorporation into the production of new products (recycling) without limiting the production of polymers, which possess unique properties, such as their lightweight, low cost, ability to keep out moisture and air, and the potential for recycling.

Despite the unique properties of plastic, the global attitude towards it is mixed. Earlier this year, the Centre for Climate Integrity (CCI) released a provocative report accusing international petrochemical companies of deceiving the public for years by claiming that plastic recycling is feasible on an industrial scale. The environmental group stated that most plastic waste cannot be recycled due to technological and economic constraints. One of the arguments the CCI presented to support its conclusions was that “the quality of plastic degrades as it is recycled,” limiting its use and further recyclability.

A recent study by the Russian Chemists Union completely refutes this claim, proving that the most common (high-tonnage) types of polymers – PP, LDPE, HDPE, PVC, and PS – can be successfully recycled multiple times without losing their consumer properties. Experiments conducted with the participation of Rosbiotech University and other scientific organisations showed that low-density polyethylene (LDPE) and polyvinyl chloride (PVC) retain their consumer properties after being recycled 10 times; high-density polyethylene (HDPE), 9 times; polypropylene, 8 times; and polystyrene, 5 times.

The scientists involved in the study evaluated the quality of the recycled materials using six indicators: molecular weight, breaking stress, relative elongation at break, oxygen-containing groups, yellowing, and melt flow.

Russia plans to develop a methodology for recycling basic polymers and determining their possible applications. It will become increasingly common for environmentally responsible companies to produce goods from recycled plastic. By developing recycling, it will be possible to reduce the environmental fees that polymer processors could face in the future.

The Russian Chemists Union confirmed that polymers offer excellent potential for use in a circular economy. According to industry estimates, more than 60% of the 5 million tonnes of plastic waste generated annually in Russia could potentially be recycled and used in the production of new products, including packaging.

SIBUR, Russia’s largest polymer producer, is increasingly incorporating recycled raw materials into its production. SIBUR already employs mechanical recycling of plastic waste – PET, LDPE, PP, and others – to produce eco-friendly polymers, under its Vivilen brand, with up to 70% recycled content.

The company is preparing to launch chemical recycling (thermolysis), which will enable the incorporation of hard-to-recycle plastic waste into production. This technology, through sorting, high temperature (400°C), and pressure, turns polymer waste into aquathermolysis “oil” that can be separated into different fractions – from naphtha to light gas oil – and used as raw materials for polymer production.

Thus, polymers are increasingly being incorporated into the production of new products, benefiting both the environment and the economy. Polymers have become a circular-economy product, and as the Russian Chemists Union confirmed, they have the potential to be recycled multiple times.